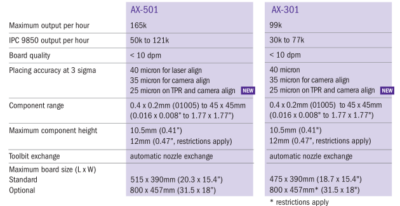

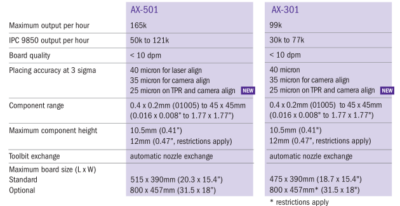

AX-301 Pick & Place System Specifications:

- Base length : 2.7m

- Up to 156 feeding lanes

- Up to 47 trays

- Confi gurable up to 77 kcph (IPC 9850)

- Board sizes up to 475 x 390mm

- Optional board width 457mm

AX-301 Pick & Place System Specifications:

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

| Model | YRM20 | ||

|---|---|---|---|

| Super high-speed rotary RM head | High-speed general-purpose in-line HM head | Odd-shaped components in-line FM (flexible-multi) head | |

| Nozzles (per 1 head unit) | 18 | 10 | 5 |

| Applicable components | 0201mm to W12 x L12mm, Height 6.5mm or less | 0201mm to W55 x L100mm, Height 15mm or less | 03015mm to W55 x L100mm, Height 30mm or less |

| Mounting capability (under optimum conditions) | 120,000CPH Note 1 | 100,000CPH Note 1 | 35,000CPH |

| Mounting accuracy (under optimum conditions) | ±0.015mm Cpk≧1.0 Note 2 | ±0.035mm Cpk≧1.0 | |

| Number of component types | Feeder carriage exchange : Max. 128 types = 32 feeders x 4 (conversion for 8mm tape feeder) Fixed plate : Max. 128 types (conversion for 8mm tape feeder), Trays : 60 types (maximum when equipped with eATS30 x 2) | ||

| PCB dimensions | Single use : L50 x W50mm to L810 x W610mm Dual use : L50 x W50mm to L810 x W330mm | ||

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz | ||

| Air supply source | 0.45MPa or more, in clean, dry state | ||

| External dimension (excluding projections) | L1,374 x W2,102 x H1,445mm | ||

| Weight | Approx. 2,550kg (Main unit only) | ||

| S10 | S20 | |

|---|---|---|

| Board size(with buffer unused) | Min. L50 x W30mm to Max. L1,330 x W510mm (Standard L955) | Min. L50 x W30mm to Max. L1,830 x W510mm (Standard L1,455) |

| Board size(with input or output buffer used) | Min. L50 x W30mm to Max. L420 x W510mm | - |

| Board size(with input and output buffers used) | Min. L50 x W30mm to Max. L330 x W510mm | Min. L50 x W30mm to Max. L540 x W510mm |

| Board thickness | 0.4 - 4.8mm | 0.4 - 4.8mm |

| Board flow direction | Left to right (Std) | Left to right (Std) |

| Board transfer speed | Max 900mm/sec | Max 900mm/sec |

| Placement speed (12 heads + 2 theta) Opt. Cond. | 0.08sec/CHIP (45,000CPH) | 0.08sec/CHIP (45,000CPH) |

| Placement accuracy A (μ+3σ) | CHIP +/-0.040mm | CHIP +/-0.040mm |

| Placement accuracy B (μ+3σ) | IC +/-0.025mm | IC +/-0.025mm |

| Placement angle | +/-180 degrees | +/-180 degrees |

| Z axis control / Theta axis control | AC servo motor | AC servo motor |

| Component height | Max 30mm*1 (Pre-placed components: max 25mm) | Max 30mm*1 (Pre-placed components: max 25mm) |

| Applicable components | 0201mm – 120x90mm, BGA, CSP, connector, etc. (Standard 01005 -) | 0201mm – 120x90mm, BGA, CSP, connector, etc. (Standard 01005 -) |

| Component package | 8 - 56mm tape (F1/F2 Feeders), 8 - 88mm tape (F3 Electric Feeders), stick, tray | 8 - 56mm tape (F1/F2 Feeders), 8 - 88mm tape (F3 Electric Feeders), stick, tray |

| Drawback check | Vacuum check and vision check | Vacuum check and vision check |

| Screen language | English, Chinese, Korean, Japanese | English, Chinese, Korean, Japanese |

| Board positioning | Board grip unit, front reference, auto conveyor width adjustment | Board grip unit, front reference, auto conveyor width adjustment |

| Component types | Max 90 types (8mm tape), 45 lanes x 2 | Max 180 types (8mm tape), 45 lanes x 4 |

| Transfer height | 900 +/- 20mm | 900 +/- 20mm |

| Machine dimensions, weight | L1250xD1750xH1420mm, Approx. 1,200kg | L1750xD1750xH1420mm, Approx. 1,500kg |

| Model | YSM20WR |

|---|---|

| Applicable PCB | Dual lane Note 1 Same type PCBs: L810 x W356 to L50 x W50 Different type PCBs: up to L810 x W662 Note 2 Same type PCB: L810 x W280 to L50 x W500 Different type PCBs: up to L810 x W510 |

| Head / Applicable components | High-Speed Multi (HM) Head Note 3 0201mm to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015mm to W55 x L100mm, Height 28mm or less |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) | X axis 2-beam Note 1: High-speed multi-purpose (HM: High-speed Multi) head x 2 81,000CPH |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 2,110 x H1,445mm (Main unit only) |

| Weight | Approx. 2,500kg (Main unit only) |

Product Enquiry

Reviews

There are no reviews yet.