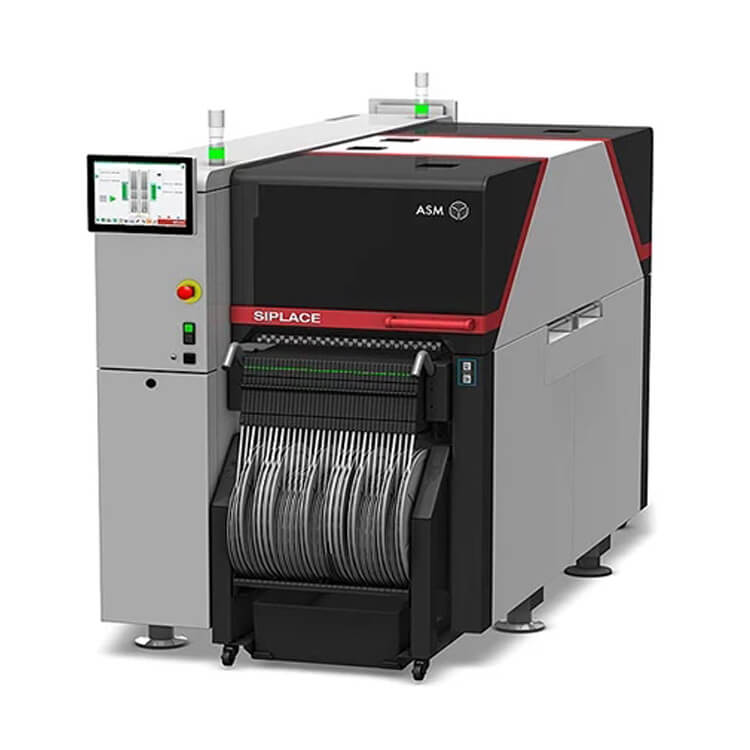

SMT placement machine ASM Siemens placement machine TX2i/TX2/TX1

Introduction to ASM Siemens Mounter TX2i: ASM Siemens Mounter TX2i: Provide high performance and high precision in a very small footprint. The ASM Siemens Mounter TX2i mounter module sets a new benchmark for mass production. No other placement solution can achieve 25 µm @ 3 sigma accuracy at speeds up to 96,000 cph in such a small footprint (only 1m x 2.3m).

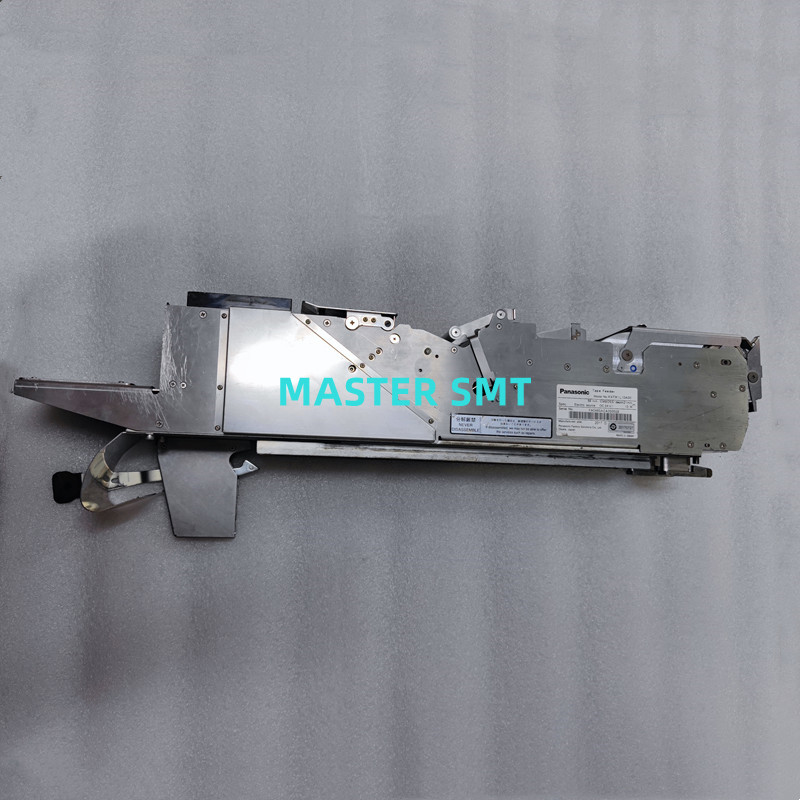

SMT placement machine Panasonic/Panasonic BM231 placement machine

Panasonic’s BM231 modular high-speed multi-function placement machine has any volume, any mix capability by placing various components from 0402 (01005) microchips to BGAs, CSPs and connectors. Maximum productivity is achieved through uninterrupted operation and quick changeovers.

SMT placement machine Samsung placement machine SM471Plus

High-performance chip shooter with a new fly camera

· World’s highest speed of 78,000CPH among chip shooters of the same class

· With two gantry dual-lane construction, supports various production modes

-

Specifications

- Alignment

- Fly Camera

- Spindle & Speed

- 2 Gantry * 10 Spindle / 78,000 CPH

- Accuracy

- ±40μm@±3σ (Chip) / ±50μm@±3σ (QFP)

- Component Range

- 0402 ~ □14mm

- Dimension

- L 1,650 x D 1,690 x H 2,045

SMT placement machine Siemens ASM SIPLACE HS50 high-speed placement machine

1. The size of the parts that can be attached: from 0201 (0.25mmx0.5mm) to 18.7mmx18.7mm.

2. The types of parts that can be loaded at one time: 144 types (8mm parts).

3. SMT speed: 50,000 parts/hour.

4. Chip accuracy: ±0.075 (at 4sigma).

5. Material station: 144

SMT Samsung Mounter SM481Plus 481

Specifications

- Alignment

- Fly Camera + Fix Camera (Option)

- Spindle & Speed

- 1 Gantry * 10 Spindle / 40,000 CPH

- Accuracy

- ±40μm@±3σ (Chip) / ±30μm@±3σ(QFP)

- Component Range

- Fly: 0402 ~ □16mm / Fix: ~□55mm, L75mm Connector

- Dimension

- L 1,650 x D 1,680 x H 2,090

σ/QFP

SMT Samsung Mounter SM482 Plus 482

Specifications

- Alignment

- Fly Camera + Fix Camera (Option)

- Spindle & Speed

- 1 Gantry * 6 Spindle / 30,000 CPH

- Accuracy

- ±40μm@±3σ (Chip) / ±30μm@±3σ(QFP)

- Component Range

- Fly: 0603 ~ □22mm(0402 ~ □14mm) / Fix: ~□55mm, L75mm Connector

- Dimension

- L 1,650 x D 1,680 x H 2,090

Super High Efficiency Dual Lane Modular YRM20DL Mounter placement machine

Specifications

| Model | YRM20 | ||

|---|---|---|---|

| Super high-speed rotary RM head | High-speed general-purpose in-line HM head | Odd-shaped components in-line FM (flexible-multi) head | |

| Nozzles (per 1 head unit) | 18 | 10 | 5 |

| Applicable components | 0201mm to W12 x L12mm, Height 6.5mm or less |

0201mm to W55 x L100mm, Height 15mm or less |

03015mm to W55 x L100mm, Height 30mm or less |

| Mounting capability (under optimum conditions) |

120,000CPH Note 1 | 100,000CPH Note 1 | 35,000CPH |

| Mounting accuracy (under optimum conditions) |

±0.015mm Cpk≧1.0 Note 2 | ±0.035mm Cpk≧1.0 | |

| Number of component types | Feeder carriage exchange : Max. 128 types = 32 feeders x 4 (conversion for 8mm tape feeder) Fixed plate : Max. 128 types (conversion for 8mm tape feeder), Trays : 60 types (maximum when equipped with eATS30 x 2) |

||

| PCB dimensions | Single use : L50 x W50mm to L810 x W610mm Dual use : L50 x W50mm to L810 x W330mm |

||

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz | ||

| Air supply source | 0.45MPa or more, in clean, dry state | ||

| External dimension (excluding projections) |

L1,374 x W2,102 x H1,445mm | ||

| Weight | Approx. 2,550kg (Main unit only) | ||