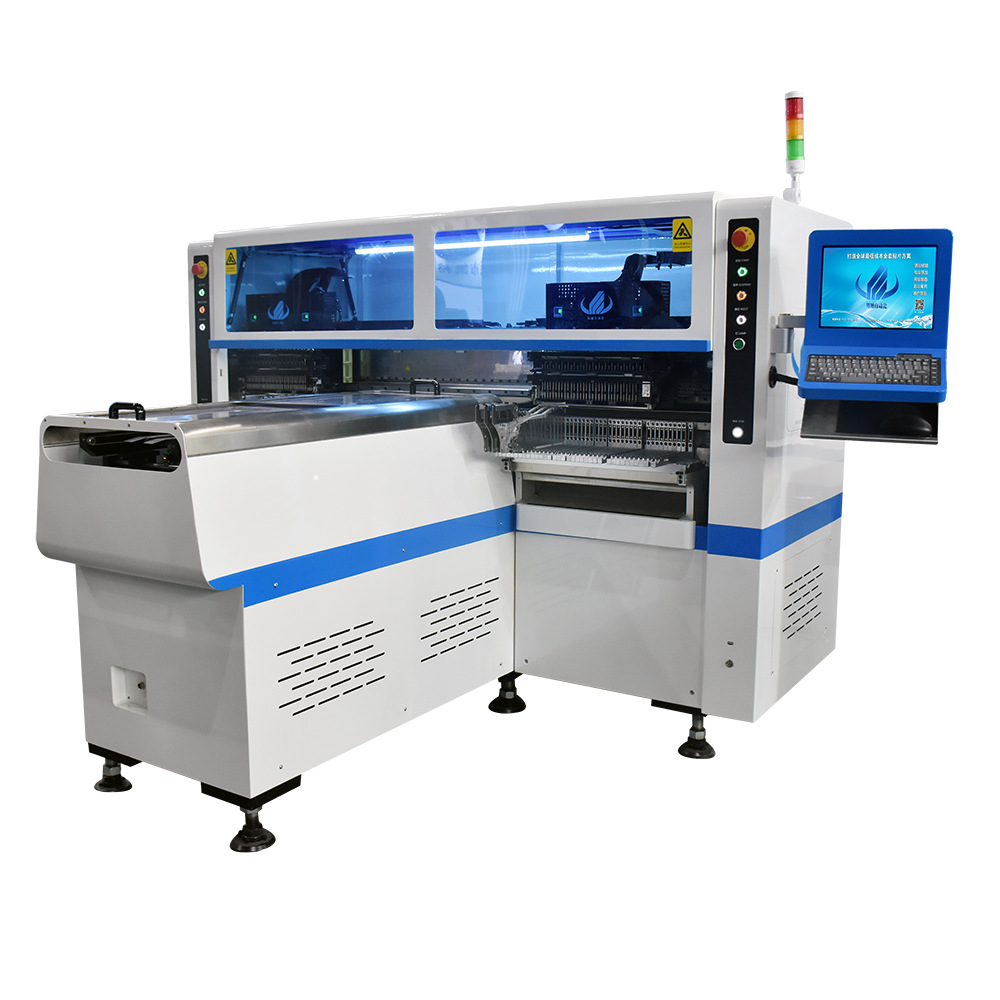

| HT-F9 specification | ||

| Diemension | L | 2700mm |

| W | 2120mm | |

| H | 1550mm | |

| Weight | 1400Kg | |

| PCB | PCB SIZE | Up to:330*1200mm Min:330*80mm |

| PCB thickness | Thickness: 0.5 to 5mm | |

| PCB board fixing method | Software automatic adjustment, fixed PCB board | |

| place method | Group pick group place | |

| operating system | system | Windows 7 |

| softwareIndependent research and development | ||

| monitor | touch LED display | |

| input device | keyboard, mouse | |

| visual system | Number of cameras | Five sets of imported cameras |

| Visual alignment, MARK correction | ||

| Repeatability | ±0.02mm | |

| place height | 〈13mm | |

| place speed | 200000 CPH | |

| Mounting component range | Led beads 3014/3020/3528/5050, capacitors, resistors and bridge rectifier, etc. | |

| Component span | 0.2mm | |

| feeder numbers | 68 | |

| nozzle numbers | 68 | |

| power supply | 380AC 50Hz | |

| power | 6KW | |

| use environment | 23℃±3℃ | |

| Rail driveThe maximum length | 1200mm | |

| transfer speed | >500mm/sec | |

| Transmission direction | One-way (left → right or right → left) | |

| transmission method | online | |

| Targeting | optics | |

| air pressure | >5.0Kg/ CM² | |

| electrical control | ETON independent research and development | |

| Motion control card module 1 set | ETON independent research and development | |

| XY axis drive mode | Y axis linear motor, X, Z axis servo motor control | |

| Feeding method | Dual motor electric feeder | |

ETON HT-F9 Magnetic levitation high-speed placement machine Pick&Place machine

Enquiry

Categories: MADE IN CHINA MACHINE, SMT placement machine

Description

Shipping & Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Be the first to review “ETON HT-F9 Magnetic levitation high-speed placement machine Pick&Place machine” Cancel reply

Related products

SMT placement machine SIPLACE ASM Siemens D4/D3/D2/D1 high-speed placement machine

SMT Samsung Mounter SM481Plus 481

SMT placement machine Samsung placement machine SM471Plus

High-performance chip shooter with a new fly camera

· World's highest speed of 78,000CPH among chip shooters of the same class

· With two gantry dual-lane construction, supports various production modes

-

Specifications

- Alignment

- Fly Camera

- Spindle & Speed

- 2 Gantry * 10 Spindle / 78,000 CPH

- Accuracy

- ±40μm@±3σ (Chip) / ±50μm@±3σ (QFP)

- Component Range

- 0402 ~ □14mm

- Dimension

- L 1,650 x D 1,690 x H 2,045

Yamaha Ultra-High-Speed Modular Z:TA-R YSM40R Mounter placement machine

Specifications

| Z:TA-R YSM40R | ||

|---|---|---|

| 4-Beam, 4-Head Spec. (YSM40R-4) | ||

| Applicable PCB | L700×W460mm to L50×W50mm | |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) | 200,000CPH (When using RS head) | |

| Applicable components | Ultra-High-Speed (RS) Head | 0201mm* to □6.5mm (Height 2.0mm or less) *option |

| Multi (MU) Head | 03015mm to 45×60mm (Height 15mm or less) | |

| Mounting accuracy (Under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) | +/-35μm (25μm) Cpk ≧1.0 (3σ) | |

| Number of component types * 8mm width tape conversion | Max. 80 feeders with RS heads Max. 88 feeders with MU heads Max. 84 feeders with RS x 2 + MU x 2 heads | |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% | |

| Air supply source | 0.45MPa or more, in clean, dry state | |

| External dimension | L1,000×W2,100×H1,550mm (excluding projections) | |

| Weight | Approx. 2,100 kg | |

SMT placement machine Siemens ASM SIPLACE HS50 high-speed placement machine

SMT placement machine ASM Siemens placement machine TX2i/TX2/TX1

Introduction to ASM Siemens Mounter TX2i: ASM Siemens Mounter TX2i: Provide high performance and high precision in a very small footprint. The ASM Siemens Mounter TX2i mounter module sets a new benchmark for mass production. No other placement solution can achieve 25 µm @ 3 sigma accuracy at speeds up to 96,000 cph in such a small footprint (only 1m x 2.3m).

SMT ASM Siemens Mounter HS60/SIPLACE High Speed Mounter

Panasonic NPM-W2 Multifunctional Mounter placement machine

Product Features of Panasonic NPM-W2 Multi-Function Mounter

1. Install & inspect a complete system to achieve efficient and high-quality production

To match the actual installation requirements, you can choose high-yield or high-precision mode

2. Can correspond to larger substrates and large components

Correspondingly, on a large substrate of 750×550 mm, the component range is also expanded to L150×W25×T30mm

3. Double-track installation (select specifications) to achieve high productivity per unit area

According to the production substrate, you can choose independent mounting, alternate mounting, mixed mounting and other mounting methods

Reviews

There are no reviews yet.